Product Categories

All Products

-

White FEP Rod

FEP rod is made from FEP resin and prepared by the technology of extrusion and molding.FEP rod remains basically the properties of PTFE, like excellent high- low-temperature resistance, chemical stability, dielectricity, high non-adhesiveness and mechanical strength.it can be machined into various sealing parts and electric components. It can be used at the temperature range of -80 through +200.

-

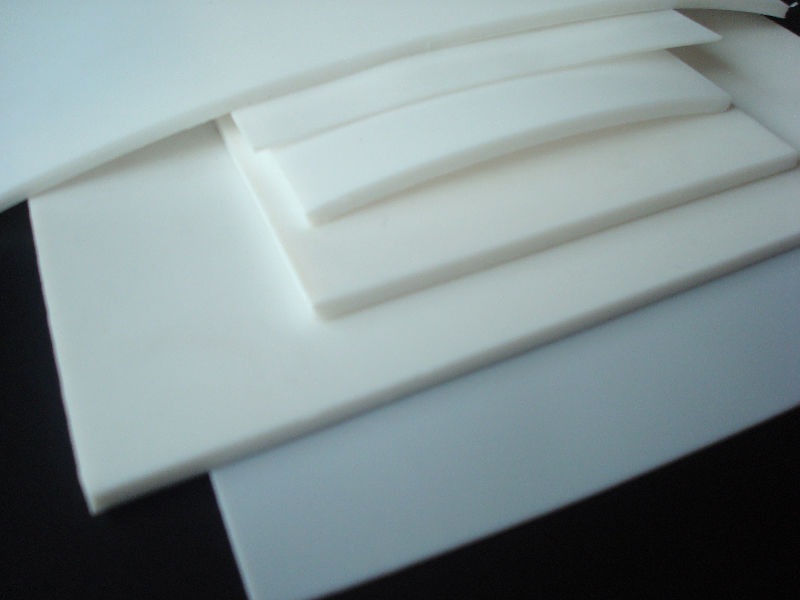

Window FEP Tube FEP Sheet High Insulation

FEP sheet is made from FEP resin and prepared by the technology of molding. FEP sheet remains basically the properties of PTFE, like excellent high- low-temperature resistance, chemical stability, dielectricity, high non-adhesiveness and mechanical strength.it can be machined into various sealing parts and electric components. It can be used as sealing part, wear-resistant component and electric component under the condition of high frequency and corrosive media at the temperature of -80 through +200. FEP sheets are produced in two different forms, which are molding sheets and skived sheets. Molding sheets are made from PTFE suspension resins. And lathed sheets are made from semi-finished PTFE materials.

-

Industrial Fluorinated Ethylene Propylene Tube FEP Heat Shrink Tubing

FEP tube is slightly less chemically inert than PTFE but exhibits much lower diffusion through its wall making it ideal for transporting aggressive gases for various forms of monitoring & analysis. A high degree of optical clarity together with the very smooth internal surface of FEP tube make it the perfect choice for sight-glasses & coloured paint delivery systems that require the liquid flow to be observed easily without the inconvenience of internal residue build-up. FEP Tubing is also available in coiled tubing that can be ordered in various sizes, lengths, special sizes and colors to meet your needs

-

PCTFE Rod

PCTFE Rod has the best performance of gas barrier properties, especially for low permeation capability to moisture and steam atmosphere compared with other plastics. The heat resistance and chemical resistance capabilities are lesser than PFA and FEP, however, mechanical characteristics (especially hardness) are superior.

-

300mm Width PCTFE Sheet For Piping Parts With Chemical Resistance

PCTFE sheet is inert to chemicals and functions over a -200 oC to +150 oC temperature range. PCTFE has excellent electrical properties and may be machined to precise dimensions. Compression, impact and tensile strength are high over a wide temperature range. It has excellent rigidity, low temperature resistance, cryogenic fluid resistance, and airflow resistance. It has special application in the high new technical areas.

-

PCTFE Tube For Instrumentation

PCTFE tube has the best performance of gas barrier properties, especially for low permeation capability to moisture and steam atmosphere compared with other plastics. The heat resistance and chemical resistance capabilities are lesser than PFA and FEP, however, mechanical characteristics (especially hardness) are superior.

-

Acid-Resistant PCTFE Rod

PCTFE Rod has the best performance of gas barrier properties, especially for low permeation capability to moisture and steam atmosphere compared with other plastics. The heat resistance and chemical resistance capabilities are lesser than PFA and FEP, however, mechanical characteristics (especially hardness) are superior.

-

Brown PEEK Rods

PEEK sheet can be used at high temperature continuously almost 260 cent degrees, and without losing its physical properties and chemical properties. PEEK shows high stiffness and hardness, and an unique high tensile strength and fatigue strength. PEEK provides good dielectric properties when the temperature ups to +260 cent degrees. PEEK can be used with chemicals except for concentrated sulfuric acid, and additionally has low metal ion elution and gas discharge properties. It can also be welded.

-

Recycled PEEK Tube

PEEK tube can be used at high temperature continuously almost 260 cent degrees, and without losing its physical properties and chemical properties. PEEK shows high stiffness and hardness, and an unique high tensile strength and fatigue strength. PEEK provides good dielectric properties when the temperature ups to +260 cent degrees.

-

High Elastic PEEK Rods

PEEK tube can be used at high temperature continuously almost 260 cent degrees, and without losing its physical properties and chemical properties. PEEK shows high stiffness and hardness, and an unique high tensile strength and fatigue strength. PEEK provides good dielectric properties when the temperature ups to +260 cent degrees.