Product Categories

All Products

-

Braided Packing For Pumps , Industrial Gland packing High Temperature Resistance Ceramic

Ceramic fibre packing is braided with high quality ceramic fiber without ant impregnant. Ceramic packing is braided without any flammability component.This kind of gland Packing is static sealing packing.Ceramic fibre packing has many excellent capabilities of high strength and high temperature resistant, better insulation,incombustible,etc,It can be impregnated with graphite latex.This kind of graphite ceramic fibre packing is used in sealing of high temperature and high pressure.It can be reinforced with stainless steel or glass fibre.This will make much improvement to Ceramic Fibre Packing.

-

Fiberglass Braided Gland Packing For Pumps Industrial Gland packing Good Sealing Properties

Fiberglass Braided Packing is diagonally braided from textured glass-fiber yarn, impregnated through out with PTFE emulsion, silicone-free break in lubricant. It is very dense and supple packing, good chemical resistance.

-

Industrial PTFE Gland Packing / Higher Strength And Better Corrosion Ramie Packing

Ramie fiber packing is very soft and easy to be impregnated.It turn to be with higher strength, better corrosion and attrition resistance after impregnation of PTFE dispersion. The packing made of ramie fiber has very slim attrition to the shaft, so it’s an ideal material to be used in sea water ,clean water with low temperature, low speed, and equipment with the media of food, oil, and fruit juicy,ect.

-

Perfect Mechanical Strength And Long Elongations PU Sheets PU Squeegee

1 Excellent resistance and minimum swell to a wide range of pastes.inls and solvents 2 Ultra high durabirily-longer lifespan 3 Preciely finished edges 4 Super solvent resistance

-

Weather-resistant And Anti-aging PU Sheets PU Screen Mesh Durable For Insect Preventing

Weather-resistant And Anti-aging PU Sheets PU Screen Mesh Durable For Insect Preventing

-

Solvent Resistance PU Sheets PU Scraper Blades For Mixing Machine And Conveyor Belt

Solvent Resistance PU Sheets PU Scraper Blades For Mixing Machine And Conveyor Belt

-

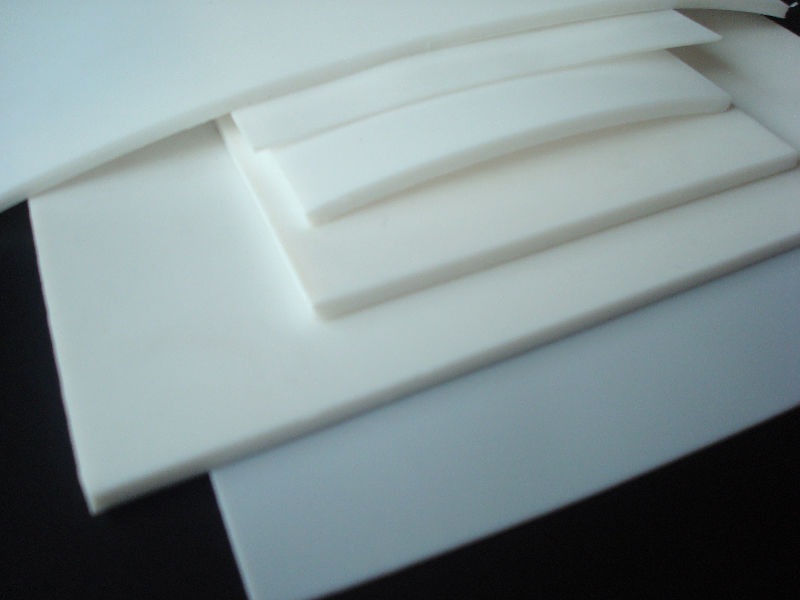

White PTFE Teflon Sheet Recycled , Poly Tetra Fluoro Ethylene

Molded PTFE Teflon sheet is manufactured by molding process with PTFE granular resin and sintering. It has a wide range of practicable temperature from -180C~+260C and a wax-like surface to which anything hardly sticks. Molded Teflon sheet has the lowest coefficient of friction of all known solid materials. Molded Teflon Blocks has the best electrical properties of all plastic.It is very suitable for seals,linings, diaphragm,scraper guide and bearing pad for bridge.

-

Natural White Polytetrafluoroethylene PTFE / Glass Filled PTFE

Molded PTFE Teflon sheet is manufactured by molding process with PTFE granular resin and sintering. It has a wide range of practicable temperature from -180C~+260C and a wax-like surface to which anything hardly sticks. Molded Teflon sheet has the lowest coefficient of friction of all known solid materials. Molded Teflon Blocks has the best electrical properties of all plastic.It is very suitable for seals,linings, diaphragm,scraper guide and bearing pad for bridge.

-

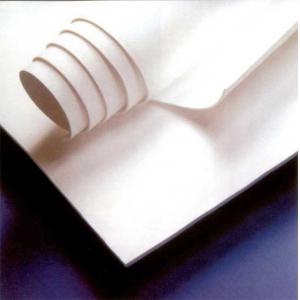

Skived PTFE Teflon Sheet / White Teflon Sheet Material 50mm Thickness

PTFE resin is first molded into work-blank and then skived. Skived PTFE Teflon sheets are known as flexible or thin sheets.It recognized as the first fluorocarbon material in the world and referred to as PTFE or Teflon, it is the most chemically resistant plastic known. It has a working temperature range of minus -180°c to 260°c It also has a very low coefficient of friction excellent thermal and electrical insulation properties and is commonly used in food contact applications. It provides good thermal stability and has good electrical properties, but is not suitable for wear application and is difficult to bond.

-

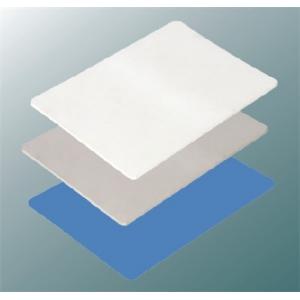

High Density Carbon Filled Teflon Sheet Material 2.1 - 2.3 g/cm³

Filled teflon PTFE sheet is manufactured by technics of molding with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of molded teflon PTFE sheet has similar friction levels to ice. Filled PTFE Teflon sheet can work at -180°C ~+260°C and is the best electrical insulator of all known plastics.Filled PTFE sheet has strong corrosion resistance and friction-resistance,By adding filler such as glass fiber,carbon fiber,copper powder,graphite,asbestos,MOS2,AL2O3,carbon powder, ceramic fiber,metal powder,polyamide,PS,the hardness,compression strength and abrasion resistance of the products is improved ,in addition,it will have good heat conductivity and low heat expansion coefficient