Product Categories

All Products

-

White Filled PTFE Teflon Tube

Filled teflon PTFE tube is manufactured by technics of molding method in the diameter from 0.5mm to 1800mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of filled teflon PTFE tube has similar friction levels to ice. Filled teflon PTFE tube can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. Filled teflon PTFE tube has strong corrosion resistance and friction-resistance,By adding filler such as glass fiber,carbon fiber,copper powder,graphite,asbestos,MOS2,AL2O3,carbon powder,ceramic fiber,metal powder,polyamide,PS,the hardness,compression strength and abrasion resistance of the products is improved ,in addition,it will have good heat conductivity and low heat expansion coefficient

-

Black PTFE Teflon Tubing

Filled teflon PTFE tube is manufactured by technics of molding method in the diameter from 0.5mm to 1800mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of filled teflon PTFE tube has similar friction levels to ice. Filled teflon PTFE tube can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. Filled teflon PTFE tube has strong corrosion resistance and friction-resistance,By adding filler such as glass fiber,carbon fiber,copper powder,graphite,asbestos,MOS2,AL2O3,carbon powder,ceramic fiber,metal powder,polyamide,PS,the hardness,compression strength and abrasion resistance of the products is improved ,in addition,it will have good heat conductivity and low heat expansion coefficient

-

4000mm High Purity PVDF Sheet

PVDF rod (polyvinylidene fluoride)/ Kynar rod, is a versatile fluoropolymer which is both strong and tough as reflected by its tensile properties and impact strengths. PVDF has excellent resistances to creep and fatigue. In thin sections, such as films, filament, and tubing, PVDF components are flexible and transparent. PVDF resin is produced by the Pennewalt and Soltex companies and sold under their respective tradenames of Kynar and Solef.

-

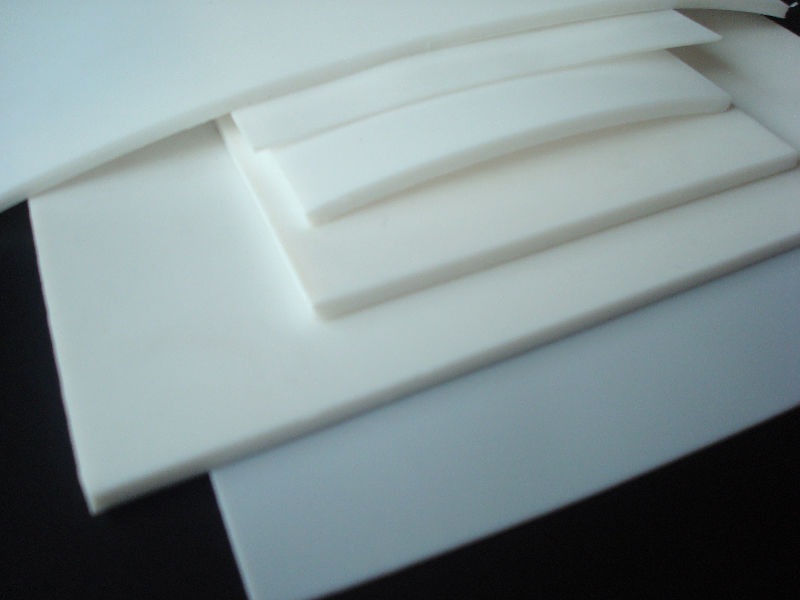

Low Water Absorption PVDF Sheet

PVDF sheet (polyvinylidene fluoride), is a versatile fluoropolymer which is both strong and tough as reflected by its tensile properties and impact strengths. PVDF has excellent resistances to creep and fatigue. In thin sections, such as films, filament, and tubing, PVDF components are flexible and transparent. PVDF resin is produced by the Pennewalt and Soltex companies and sold under their respective tradenames of Kynar and Solef. Where load bearing is important, PVDF fluoropolymers are rigid and resistant to creep under mechanical stress and load. Because PVDF is stable to sunlight, and other sources of ultraviolet radiation, it is widely used as base resins for long-lasting exterior coatings. An additional advantage over other fluoroplastics is that PVDF can be welded into tanks for acid and corrosive chemical processing in elevated temperature environments.

-

Acid-Resistant Light Weight PVDF Tube

PVDF tube (polyvinylidene fluoride)/Kynar tube, is a versatile fluoropolymer which is both strong and tough as reflected by its tensile properties and impact strengths. PVDF has excellent resistances to creep and fatigue. In thin sections, such as films, filament, and tubing, PVDF components are flexible and transparent. PVDF resin is produced by the Pennewalt and Soltex companies and sold under their respective tradenames of Kynar and Solef.

-

Alkali-Resistant PVDF Tube

PVDF tube (polyvinylidene fluoride)/Kynar tube, is a versatile fluoropolymer which is both strong and tough as reflected by its tensile properties and impact strengths. PVDF has excellent resistances to creep and fatigue. In thin sections, such as films, filament, and tubing, PVDF components are flexible and transparent. PVDF resin is produced by the Pennewalt and Soltex companies and sold under their respective tradenames of Kynar and Solef.

-

Anti-Corrosion PTFE Balls

PTFE Teflon ball is a unique product. It has many advantages in applications where metals or alloys can not be used. These advantages are Broad operating temperature (-400oF to +500oF), Chemical inertness to most corrosive liquids or gases extremely low coefficient of friction. PTFE balls are highly functional in self lubricating conditions such as ball bearings. In the fluid handling industry PTFE balls are used in ball valves that have contact with extremely corrosive liquids. PTFE ball has reduced maintenance costs and man hours in the field by eliminating the replacement of valve components subjected to corrosive environments.

-

PTFE Material With High Pressure Resistance For Automobile Part

PTFE Teflon ball is a unique product. It has many advantages in applications where metals or alloys can not be used. These advantages are Broad operating temperature (-400oF to +500oF), Chemical inertness to most corrosive liquids or gases extremely low coefficient of friction. PTFE balls are highly functional in self lubricating conditions such as ball bearings. In the fluid handling industry PTFE balls are used in ball valves that have contact with extremely corrosive liquids. PTFE ball has reduced maintenance costs and man hours in the field by eliminating the replacement of valve components subjected to corrosive environments.

-

virgin PTFE washer for Flange Sealing

PTFE washer can be named as teflon gasket, ptfe seal, ptfe cushion / washer, expanded ptfe gasket, modified ptfe gasket. The washer is molded or skived or cut from virgin PTFE powder or compounds, sheets, rods, tube etc. It has the best chemical corrosion resistance among known plastics. Without being aging, lowest friction coefficient, wear resistance. The unloaded operating temperature range is -180~+260C.

-

Radiation resistance And Aging resistance PTFE Ball For Automobile Parts

PTFE Teflon ball is a unique product. It has many advantages in applications where metals or alloys can not be used. These advantages are Broad operating temperature (-400oF to +500oF), Chemical inertness to most corrosive liquids or gases extremely low coefficient of friction. PTFE balls are highly functional in self lubricating conditions such as ball bearings. In the fluid handling industry PTFE balls are used in ball valves that have contact with extremely corrosive liquids. PTFE ball has reduced maintenance costs and man hours in the field by eliminating the replacement of valve components subjected to corrosive environments.

.jpg)