Product Categories

All Products

-

Radiation resistance And Aging resistance PTFE Ball For Automobile Parts

PTFE Teflon ball is a unique product. It has many advantages in applications where metals or alloys can not be used. These advantages are Broad operating temperature (-400oF to +500oF), Chemical inertness to most corrosive liquids or gases extremely low coefficient of friction. PTFE balls are highly functional in self lubricating conditions such as ball bearings. In the fluid handling industry PTFE balls are used in ball valves that have contact with extremely corrosive liquids. PTFE ball has reduced maintenance costs and man hours in the field by eliminating the replacement of valve components subjected to corrosive environments.

-

Expanded PTFE Coated Fiberglass Cloth For Wires

Expanded PTFE Teflon sealing tape(Teflon Sealant Joint Tape) is made with un-sintered PTFE/Teflon. PTFE is resistant to all chemical products and solvents with the exception of alkaline materials. It has good resistance to elevated pressures and has a high thermal stability. Expanded PTFE sealing tape is odourless and tasteless making it suitable for food applications and is WRC approved for use with potable water.

-

Carbon Filled PTFE Porous Membrane Polytetrafluoroethylene Sheet

PTFE micro-porous membrane Gives excellent wind-proof,water-resistant,warmth-keeping,breathable and stable per PTFE micro-porous membrane is produced by special dual-elongation process to get the light-weight and pliable film whose thinckness is 0.025mm,opening rate is 82%,and the maximum diameter of the pore is 0.2.These are about nine million pores per square inch ,and the diameter is 20 times bigger than the one of the molecular of water,20 thousand times smaller than the drop of water,which gives the film exellent wind-proof,water-resistant,warm-keeping ,breathable and stable performance.So the film is the right material to make high-class laminated fabric.

-

Recycled PTFE Coated Fiberglass Cloth High Chemical Resistance

PTFE Coated Fibreglass fabrics are available in various styles with varying PTFE content upto a maximum width of 3800mm. Additives can be incorporated in the coating to achieve various finishes as per application demands. PTFE coated fabrics are also available with Single Sided Silicone Adhesive or in Belt form with suitable Joint and Edge reinforcement as per customer requirements. The fabrics within this range are lightly coated with PTFE to achieve chemical inertness while maintaining enough p

-

Non-stick Expanded PTFE Teflon Sealing Tape Hygienic For Wires

Expanded PTFE Teflon sealing tape(Teflon Sealant Joint Tape) is made with un-sintered PTFE/Teflon. PTFE is resistant to all chemical products and solvents with the exception of alkaline materials. It has good resistance to elevated pressures and has a high thermal stability. Expanded PTFE sealing tape is odourless and tasteless making it suitable for food applications and is WRC approved for use with potable water.

-

Electrical Insulation PFA Plastic Sheet

PFA Rod is manufactured by molding and extruding method with PFA resin. PFA is the most chemical resistance of all known plastics. It does not age. It has the lowest coefficient of friction of all known solid materials and a wide range of practicable temperature from -180%° C - +260° C.

-

PVDF Material Heat Exchangers

PFA (PerFluoroAlkoxy) is similar to FEP (Polyfluoroethylenepropylene) in that PFA is a type of fluoropolymer that is similar to PTFE. PFA tubing is made from PFA resin and prepared by the technology of thermoplastic extrusion. It has good heat-resistance of -80+260,high purity and long flexible life ( 100 times of FEP tube).PFA tube is an ideal material in the applications of semi-conductor and long flexible life. Besides, PFA tube has good chemical-resistance, used as corrosive liquid and gas transportation and steel pipe liner etc. and electric insulation property. It is applied in the fields of petrochemical, semi-conductor, E/E, IT industry etc. PFA tubing is available in many standard sizes.

-

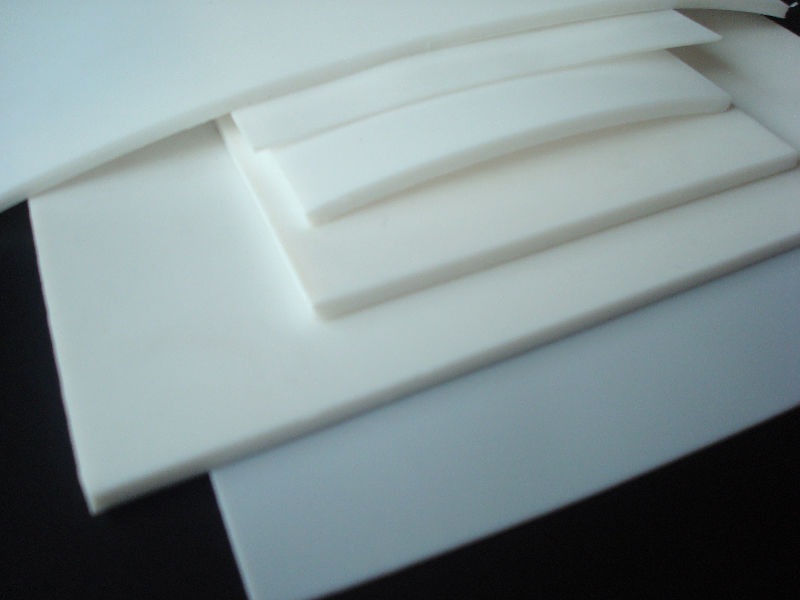

Non-Stick PFA Plastic Sheet Food Processing

PFA (also named fusible polytetrafluoroethylene) keeps PTFE excellent chemistry stability, low and high temperature resistance. PFA sheet is manufactured by molding and extruding method with PFA resin. is the most chemical resistance of all known plastics. It does not age. It has the lowest coefficient of friction of all known solid materials and a wide range of practicable temperature from -180%°C - +260°C.

-

Translucent PFA Tubing Recyclable with FEP

Description: PFA (PerFluoroAlkoxy) is similar to FEP (Polyfluoroethylenepropylene) in that PFA is a type of fluoropolymer that is similar to PTFE. PFA tubing is made from PFA resin and prepared by the technology of thermoplastic extrusion. It has good heat-resistance of -80+260,high purity and long flexible life ( 100 times of FEP tube).PFA tube is an ideal material in the applications of semi-conductor and long flexible life. Besides, PFA tube has good chemical-resistance, used as corrosive liquid and gas transportation and steel pipe liner etc. and electric insulation property. It is applied in the fields of petrochemical, semi-conductor, E/E, IT industry etc. PFA tubing is available in many standard sizes.

-

FEP Rod For Petrochemical

FEP rod is made from FEP resin and prepared by the technology of extrusion and molding.FEP rod remains basically the properties of PTFE, like excellent high- low-temperature resistance, chemical stability, dielectricity, high non-adhesiveness and mechanical strength.it can be machined into various sealing parts and electric components. It can be used at the temperature range of -80 through +200.