Product classification

PTFE

-

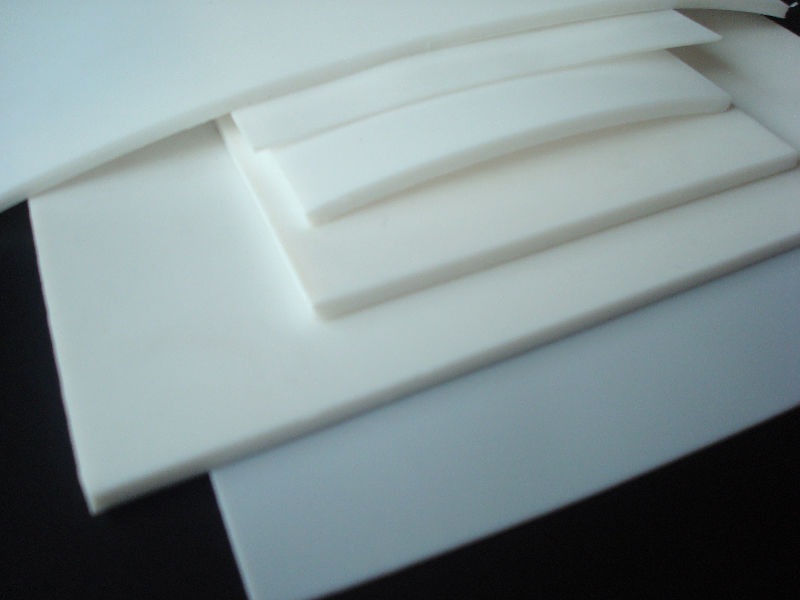

Environmental PTFE Teflon Sheet / Polytetrafluoroethylene Sheet

Molded PTFE Teflon sheet is manufactured by molding process with PTFE granular resin and sintering. It has a wide range of practicable temperature from -180C~+260C and a wax-like surface to which anything hardly sticks. Molded Teflon sheet has the lowest coefficient of friction of all known solid materials. Molded Teflon Blocks has the best electrical properties of all plastic.It is very suitable for seals,linings, diaphragm,scraper guide and bearing pad for bridge.

-

Electrical Grade PTFE Skived Sheet , PVDF Chemical Resistance

PTFE resin is first molded into work-blank and then skived. Skived PTFE Teflon sheets are known as flexible or thin sheets.It recognized as the first fluorocarbon material in the world and referred to as PTFE or Teflon, it is the most chemically resistant plastic known. It has a working temperature range of minus -180°c to 260°c It also has a very low coefficient of friction excellent thermal and electrical insulation properties and is commonly used in food contact applications. It provides good thermal stability and has good electrical properties, but is not suitable for wear application and is difficult to bond.

-

Pump PTFE Teflon Sheet Heat Resistance 2.1 - 2.3 g/cm³ High Density

Molded PTFE Teflon sheet is manufactured by molding process with PTFE granular resin and sintering. It has a wide range of practicable temperature from -180C~+260C and a wax-like surface to which anything hardly sticks. Molded Teflon sheet has the lowest coefficient of friction of all known solid materials. Molded Teflon Blocks has the best electrical properties of all plastic.It is very suitable for seals,linings, diaphragm,scraper guide and bearing pad for bridge.

-

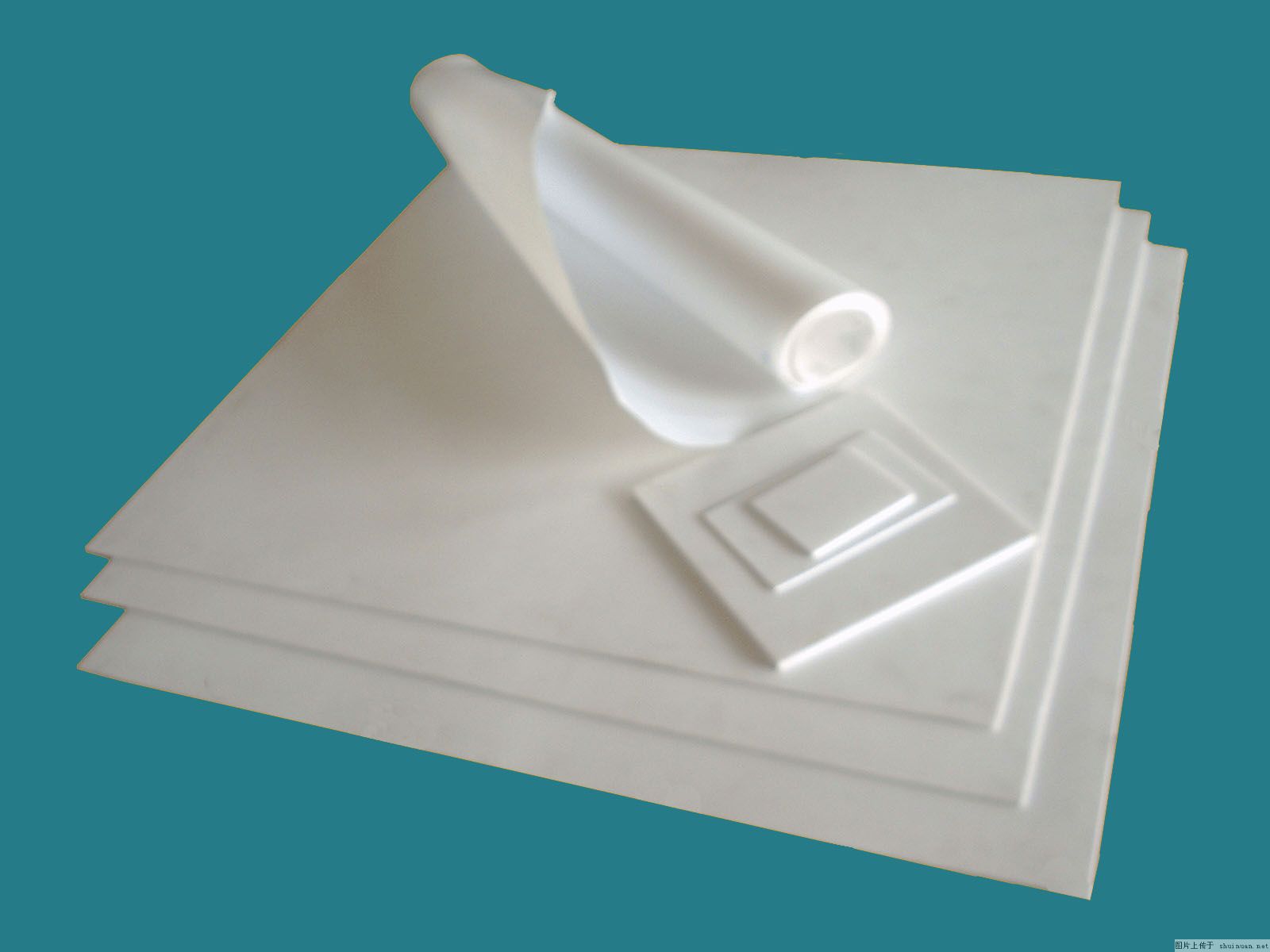

Soft Expanded Teflon Sheet , Non-Toxic Teflon Sheet For Wire Isolation

Expanded PTFE Teflon sheet is made of 100% expanded PTFE by using special process that produces a uniform and highly fibrillated microstructure with a great lot of fibers running in multi directions.PTFE Expanded Sheets gasketing possesses universal resistance against common chemicals, except melted alkali metal, fluorine at liquid and gas states. It is free from asbestos and other lung-intruding materials. It meets the FDA requirements, doesn't have any corrosion and is able to be stored without any time limits. Some of its features are that it has Good Flexibility, Good Seal ability, highly compressible, Non Contaminating, and Non Toxic etc.

-

Carbon Filled PTFE Teflon Sheet For Heat Press , Filled PTFE Sheet

Description: Filled teflon PTFE sheet is manufactured by technics of molding with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of molded teflon PTFE sheet has similar friction levels to ice. Filled PTFE Teflon sheet can work at -180°C ~+260°C and is the best electrical insulator of all known plastics.Filled PTFE sheet has strong corrosion resistance and friction-resistance,By adding filler such as glass fiber,carbon fiber,copper powder,graphite,asbestos,MOS2,AL2O3,carbon powder, ceramic fiber,metal powder,polyamide,PS,the hardness,compression strength and abrasion resistance of the products is improved ,in addition,it will have good heat conductivity and low heat expansion coefficient

-

Wire Isolation Expanded PTFE Sheet High Temperature Teflon Sheet

Expanded PTFE Teflon sheet is made of 100% expanded PTFE by using special process that produces a uniform and highly fibrillated microstructure with a great lot of fibers running in multi directions.PTFE Expanded Sheets gasketing possesses universal resistance against common chemicals, except melted alkali metal, fluorine at liquid and gas states. It is free from asbestos and other lung-intruding materials. It meets the FDA requirements, doesn't have any corrosion and is able to be stored without any time limits. Some of its features are that it has Good Flexibility, Good Seal ability, highly compressible, Non Contaminating, and Non Toxic etc.

-

Graphite Filled PTFE Teflon Sheet Material Polytetrafluoroethylene

Expanded PTFE Teflon sheet is made of 100% expanded PTFE by using special process that produces a uniform and highly fibrillated microstructure with a great lot of fibers running in multi directions.PTFE Expanded Sheets gasketing possesses universal resistance against common chemicals, except melted alkali metal, fluorine at liquid and gas states. It is free from asbestos and other lung-intruding materials. It meets the FDA requirements, doesn't have any corrosion and is able to be stored without any time limits. Some of its features are that it has Good Flexibility, Good Seal ability, highly compressible, Non Contaminating, and Non Toxic etc.

-

Low Compressive / Tensile Strength Filled PTFE Sheet For Seals

Tefon resin is first molded into work-blank and then skived. Teflon sheets are known as flexible or thin sheets.It recognized as the first fluorocarbon material in the world and referred to as PTFE or Teflon, it is the most chemically resistant plastic known. It has a working temperature range of minus -180°c to 260°c It also has a very low coefficient of friction excellent thermal and electrical insulation properties and is commonly used in food contact applications. It provides good thermal stability and has good electrical properties, but is not suitable for wear application and is difficult to bond.

-

Water resistance PTFE Teflon Sheet PTFE Slide Bearing For Pipelines

PTFE Teflon slide bearing commonly known as teflon bearing or PTFE bearing - is manufactured by technics of molding, sintering and finalizing the design to various sizes with PTFE suspension resin. It can be adhered to rubber and metal with one side etched. And different fillings can be used to achieve special demands. PTFE slide bearing can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. PTFE bearing slide is made from high strength PTFE suspension resin by methods of moulding, sintering and finalizing the design to various sizes. Different fillings can be used to achieve special demands. It can also be adhered to rubber and metal with one side etched.

-

Water resistance PTFE Teflon Sheet PTFE Slide Bearing For Pipelines

PTFE Teflon slide bearing commonly known as teflon bearing or PTFE bearing - is manufactured by technics of molding, sintering and finalizing the design to various sizes with PTFE suspension resin. It can be adhered to rubber and metal with one side etched. And different fillings can be used to achieve special demands. PTFE slide bearing can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. PTFE bearing slide is made from high strength PTFE suspension resin by methods of moulding, sintering and finalizing the design to various sizes. Different fillings can be used to achieve special demands. It can also be adhered to rubber and metal with one side etched.