Product Categories

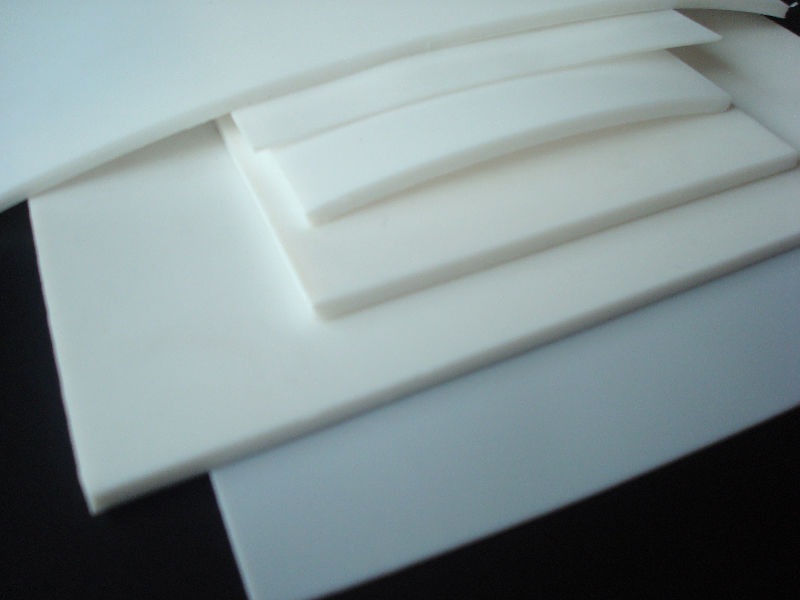

Plastic PVDF Sheet High Toughness Wear Resistant For Chemical Tank

Product number:kaxite-vd16

Quick Overview: · Easily machined · Easily bonded and welded · Resistant to most alkalis and weak acids · High heat distortion temperature · Very good electrical insulator · Excellent formability · Relatively low water absorption

Send Inquiry

PDF DownLoad

Product Description

Detailed Product Description

Related Products

4000mm High Purity PVDF Sheet / PVDF Rod For Floor , 2.10 - 2.30g/cm³

Acid-Resistant Light Weight PVDF Tube / PVDF Sheet For Pharmaceutical Industry

Alkali-Resistant PVDF Tube / PVDF Tubing For Chemical Processing 100mm

10m Easily Bonded PVDF Sheet For Semiconductor Industry , Easily Welded

2.10g/cm³ PVDF Rod With High Thermal Stability For Kitchen , 140% Elongation

150mm PVDF Tube / PVDF Tubing With High Impact Resistance For Paper Industry

Easily Machined PVDF Sheet / Polyvinylidene Fluoride For Solar Photovoltaic

14MPa Tensile Strenath PVDF Rod With High Purity For Billboards

Melt Processable Plastic PVDF Rod Corrosion Resistant , Ultraviolet Resistance

High Chemical Resistant Natural PVDF Bar 140% Elongation 14MPa Tensile Strenath

Anti-corrosion PVDF Tubing Strong Agglutination High Abrasion Resistance

Chemical Resistant PVDF Pipe , Transparant Strong Agglutination PVDF Tube

White Machined PVDF Sheet , Plastic Upvc Heat Insulation Roofing Sheet

Bonded / Welded Plastic PVDF Plate High Toughness Good Wear Resistance

High Hardness Plastic PVDF Rod , Resistance To Ultraviolet And Nuclear Radiation

High Impact Resistant Plastic PVDF Rod With High Abrasion Resistance

Plastic PVDF Sheet High Toughness Wear Resistant For Chemical Tank

Plastic Upvc Heat Insulation Roofing Sheet PVDF Sheet , Easily Machined

High Abrasion Resistant Anti-corrosion PVDF Tubes Extremely Strong Agglutination

100% Virgin Transparent PVDF Film With Good Firction And Wear / Tear Values

Nature White PVDF Sheet Easily Machined With High Chemical Resistance

Macromolecule Film PVDF Pipe Acid-Resistant And Alkali-Resistant

Extremely Strong Agglutination PVDF Tube / PVDF Sheet For Insulating Component

Ceiling High Abrasion Resistance PVDF Sheet / Bar Flexible And Transparent

High Abrasion Resistance PVDF Sheet / Rod With Polyvinylidene Fluoride

Semiconductor Industry PVDF Sheet High Strength , Light Weight PVDF

High Heat Distortion Temperature PVDF Plate , PVDF Sheet Laboratory Use

4000mm High Purity PVDF Sheet / Polyvinylidene Fluoride Rod For Floor , 2.10 - 2.30g/cm³

Low Water Absorption PVDF Sheet / Polyvinylidene Fluoride For Laboratory , Easily Machined

Easily Machined PVDF Sheet / Polyvinylidene Fluoride For Solar Photovoltaic

Acid-Resistant Light Weight PVDF Tube / PVDF Sheet For Pharmaceutical Industry

Alkali-Resistant PVDF Tube / PVDF Tubing For Chemical Processing 100mm

10m Easily Bonded PVDF Sheet For Semiconductor Industry , Easily Welded

2.10g/cm³ PVDF Rod With High Thermal Stability For Kitchen , 140% Elongation

150mm PVDF Tube / PVDF Tubing With High Impact Resistance For Paper Industry

Easily Machined PVDF Sheet / Polyvinylidene Fluoride For Solar Photovoltaic

14MPa Tensile Strenath PVDF Rod With High Purity For Billboards

Melt Processable Plastic PVDF Rod Corrosion Resistant , Ultraviolet Resistance

High Chemical Resistant Natural PVDF Bar 140% Elongation 14MPa Tensile Strenath

Anti-corrosion PVDF Tubing Strong Agglutination High Abrasion Resistance

Chemical Resistant PVDF Pipe , Transparant Strong Agglutination PVDF Tube

White Machined PVDF Sheet , Plastic Upvc Heat Insulation Roofing Sheet

Bonded / Welded Plastic PVDF Plate High Toughness Good Wear Resistance

High Hardness Plastic PVDF Rod , Resistance To Ultraviolet And Nuclear Radiation

High Impact Resistant Plastic PVDF Rod With High Abrasion Resistance

Plastic PVDF Sheet High Toughness Wear Resistant For Chemical Tank

Plastic Upvc Heat Insulation Roofing Sheet PVDF Sheet , Easily Machined

High Abrasion Resistant Anti-corrosion PVDF Tubes Extremely Strong Agglutination

100% Virgin Transparent PVDF Film With Good Firction And Wear / Tear Values

Nature White PVDF Sheet Easily Machined With High Chemical Resistance

Macromolecule Film PVDF Pipe Acid-Resistant And Alkali-Resistant

Extremely Strong Agglutination PVDF Tube / PVDF Sheet For Insulating Component

Ceiling High Abrasion Resistance PVDF Sheet / Bar Flexible And Transparent

High Abrasion Resistance PVDF Sheet / Rod With Polyvinylidene Fluoride

Semiconductor Industry PVDF Sheet High Strength , Light Weight PVDF

High Heat Distortion Temperature PVDF Plate , PVDF Sheet Laboratory Use

4000mm High Purity PVDF Sheet / Polyvinylidene Fluoride Rod For Floor , 2.10 - 2.30g/cm³

Low Water Absorption PVDF Sheet / Polyvinylidene Fluoride For Laboratory , Easily Machined

Easily Machined PVDF Sheet / Polyvinylidene Fluoride For Solar Photovoltaic