Product classification

PVDF

-

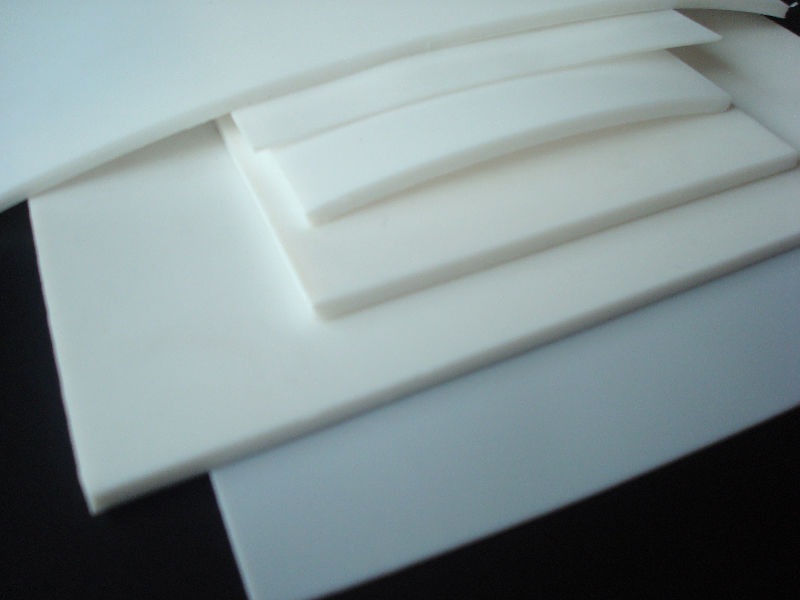

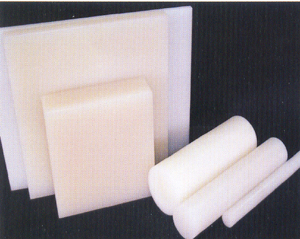

4000mm High Purity PVDF Sheet

PVDF rod (polyvinylidene fluoride)/ Kynar rod, is a versatile fluoropolymer which is both strong and tough as reflected by its tensile properties and impact strengths. PVDF has excellent resistances to creep and fatigue. In thin sections, such as films, filament, and tubing, PVDF components are flexible and transparent. PVDF resin is produced by the Pennewalt and Soltex companies and sold under their respective tradenames of Kynar and Solef.

-

4000mm High Purity PVDF Sheet / PVDF Rod For Floor , 2.10 - 2.30g/cm³

PVDF rod (polyvinylidene fluoride)/ Kynar rod, is a versatile fluoropolymer which is both strong and tough as reflected by its tensile properties and impact strengths. PVDF has excellent resistances to creep and fatigue. In thin sections, such as films, filament, and tubing, PVDF components are flexible and transparent. PVDF resin is produced by the Pennewalt and Soltex companies and sold under their respective tradenames of Kynar and Solef.

-

Acid-Resistant Light Weight PVDF Tube / PVDF Sheet For Pharmaceutical Industry

PVDF tube (polyvinylidene fluoride)/Kynar tube, is a versatile fluoropolymer which is both strong and tough as reflected by its tensile properties and impact strengths. PVDF has excellent resistances to creep and fatigue. In thin sections, such as films, filament, and tubing, PVDF components are flexible and transparent. PVDF resin is produced by the Pennewalt and Soltex companies and sold under their respective tradenames of Kynar and Solef.

-

Alkali-Resistant PVDF Tube / PVDF Tubing For Chemical Processing 100mm

PVDF tube (polyvinylidene fluoride)/Kynar tube, is a versatile fluoropolymer which is both strong and tough as reflected by its tensile properties and impact strengths. PVDF has excellent resistances to creep and fatigue. In thin sections, such as films, filament, and tubing, PVDF components are flexible and transparent. PVDF resin is produced by the Pennewalt and Soltex companies and sold under their respective tradenames of Kynar and Solef.

-

10m Easily Bonded PVDF Sheet For Semiconductor Industry , Easily Welded

PVDF sheet (polyvinylidene fluoride), is a versatile fluoropolymer which is both strong and tough as reflected by its tensile properties and impact strengths. PVDF has excellent resistances to creep and fatigue. In thin sections, such as films, filament, and tubing, PVDF components are flexible and transparent. PVDF resin is produced by the Pennewalt and Soltex companies and sold under their respective tradenames of Kynar and Solef.

-

2.10g/cm³ PVDF Rod With High Thermal Stability For Kitchen , 140% Elongation

1.Mechanical strength and toughness 2.High abrasion resistance 3.High thermal stability 4.High dielectric strength 5.High purity 6.Readily melt processable 7.Resistance to most chemicals and solvents 8.Resistance to ultraviolet and nuclear radiation 9.Resistance to weathering 10.Resistance to fungi 11.Weldable

-

150mm PVDF Tube / PVDF Tubing With High Impact Resistance For Paper Industry

1). Extremely strong agglutination, macromolecule film 2). Excellent rigidity and impact resistance 3). Acid-resistant and alkali-resistant 4). Light weight, easy to installation 5). Easy to clean and maintenance

-

Easily Machined PVDF Sheet / Polyvinylidene Fluoride For Solar Photovoltaic

· Easily machined · Easily bonded and welded · Resistant to most alkalis and weak acids · High heat distortion temperature · Very good electrical insulator · Excellent formability · Relatively low water absorption

-

14MPa Tensile Strenath PVDF Rod With High Purity For Billboards

1.Mechanical strength and toughness 2.High abrasion resistance 3.High thermal stability 4.High dielectric strength 5.High purity 6.Readily melt processable 7.Resistance to most chemicals and solvents 8.Resistance to ultraviolet and nuclear radiation 9.Resistance to weathering 10.Resistance to fungi 11.Weldable

-

Melt Processable Plastic PVDF Rod Corrosion Resistant , Ultraviolet Resistance

1.Mechanical strength and toughness 2.High abrasion resistance 3.High thermal stability 4.High dielectric strength 5.High purity 6.Readily melt processable 7.Resistance to most chemicals and solvents 8.Resistance to ultraviolet and nuclear radiation 9.Resistance to weathering 10.Resistance to fungi 11.Weldable