Product classification

PTFE Teflon Rod

-

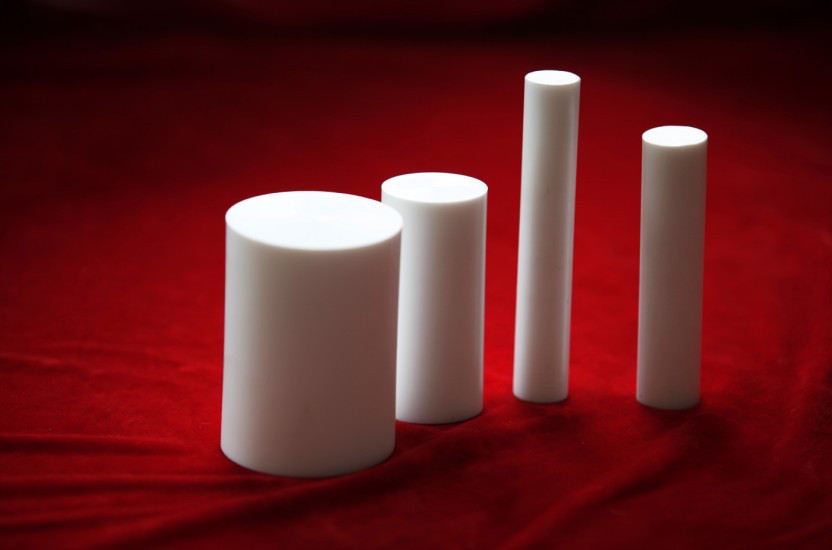

Extruded PTFE Teflon Rod

Extruded PTFE Teflon rod is manufactured by technics of paste extruding and ram extruding method in the diameter from 5 to 300mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of extruded teflon PTFE rod has similar friction levels to ice. Extruded teflon PTFE rod can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. Extruded PTFE Rod is available in both virgin grades and reprocessed (mechanical) for less demanding applications.

-

Extruded PTFE Rod

Extruded PTFE Teflon rod is manufactured by technics of paste extruding and ram extruding method in the diameter from 5 to 300mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of extruded teflon PTFE rod has similar friction levels to ice. Extruded teflon PTFE rod can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. Extruded PTFE Rod is available in both virgin grades and reprocessed (mechanical) for less demanding applications.

-

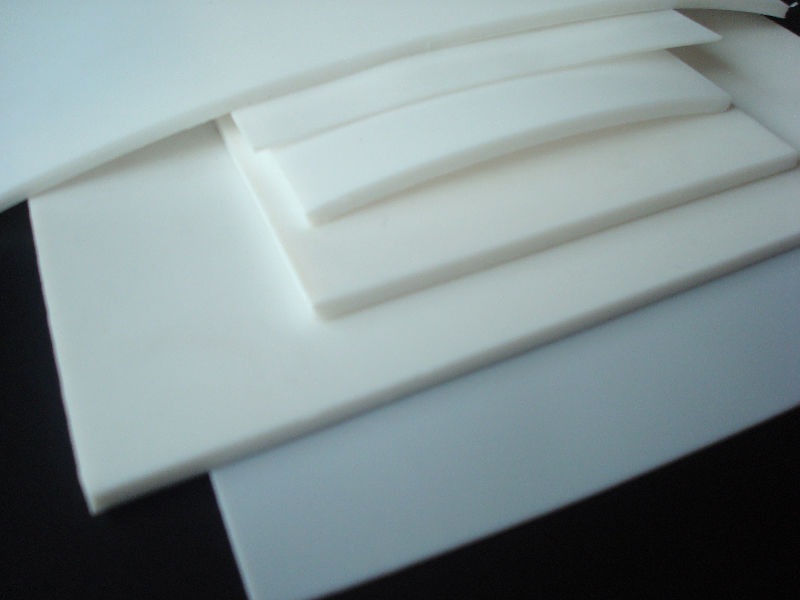

Molded PTFE Teflon Rod

Molded PTFE Teflon rod is manufactured by technics of extruding and molding method in the diameter from 10 to 500mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of molded teflon PTFE rod has similar friction levels to ice. Molded teflon PTFE rod can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. Molded Teflon rod and cylinders for machining in a wide range of sizes. The most common sizes are listed in the table below, but many other combinations of OD and ID are available. Molded rods are preferred for machining because compression molding yields greater material homogeneity for the finished part.

-

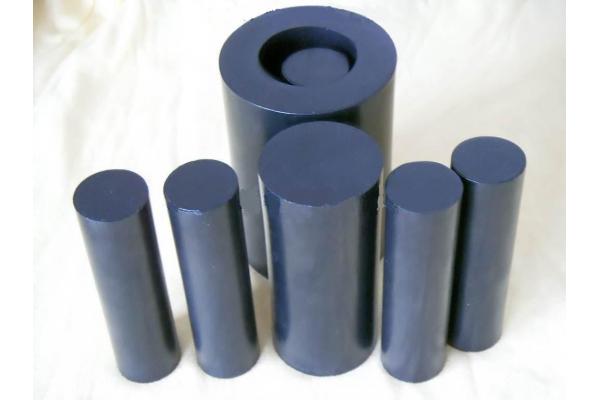

100mm Width Black Teflon Rods

Filled PTFE Teflon rod is manufactured by technics of molding method in the diameter from 5mmto 500mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of filled teflon PTFE rod has similar friction levels to ice. Extrusion teflon PTFE rod can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. Filled PTFE Teflon rod has strong corrosion resistance and friction-resistance,By adding filler such as glass fiber,carbon fiber,copper powder,graphite,asbestos,MOS2,AL2O3,carbon powder,ceramic fiber, metal powder,polyamide,PS,the hardness,compression strength and abrasion resistance of the products is improved ,in addition,it will have good heat conductivity and low heat expansion coefficient.

-

Extruded PTFE Teflon Rod / Pure White PTFE Rod For Mechanical, High Temperature Resistance

Extruded PTFE Teflon rod is manufactured by technics of paste extruding and ram extruding method in the diameter from 5 to 300mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of extruded teflon PTFE rod has similar friction levels to ice. Extruded teflon PTFE rod can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. Extruded PTFE Rod is available in both virgin grades and reprocessed (mechanical) for less demanding applications.

-

Extruded PTFE Rod / Teflon Rod For Sealing , High Chemical Resistance

Extruded PTFE Teflon rod is manufactured by technics of paste extruding and ram extruding method in the diameter from 5 to 300mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of extruded teflon PTFE rod has similar friction levels to ice. Extruded teflon PTFE rod can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. Extruded PTFE Rod is available in both virgin grades and reprocessed (mechanical) for less demanding applications.

-

Molded PTFE Teflon Rod , 3000mm Length PTFE Rod / Teflon Rods For Chemical

Molded PTFE Teflon rod is manufactured by technics of extruding and molding method in the diameter from 10 to 500mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of molded teflon PTFE rod has similar friction levels to ice. Molded teflon PTFE rod can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. Molded Teflon rod and cylinders for machining in a wide range of sizes. The most common sizes are listed in the table below, but many other combinations of OD and ID are available. Molded rods are preferred for machining because compression molding yields greater material homogeneity for the finished part.

-

100mm Width Black Teflon Rods / PTFE Rod For Chemical , Self Lubricating

Filled PTFE Teflon rod is manufactured by technics of molding method in the diameter from 5mmto 500mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of filled teflon PTFE rod has similar friction levels to ice. Extrusion teflon PTFE rod can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. Filled PTFE Teflon rod has strong corrosion resistance and friction-resistance,By adding filler such as glass fiber,carbon fiber,copper powder,graphite,asbestos,MOS2,AL2O3,carbon powder,ceramic fiber, metal powder,polyamide,PS,the hardness,compression strength and abrasion resistance of the products is improved ,in addition,it will have good heat conductivity and low heat expansion coefficient.

-

500mm Black Filled PTFE Teflon Rod / PTFE Rod / Teflon Rod For Sealing

Filled PTFE Teflon rod is manufactured by technics of molding method in the diameter from 5mmto 500mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of filled teflon PTFE rod has similar friction levels to ice. Extrusion teflon PTFE rod can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. Filled PTFE Teflon rod has strong corrosion resistance and friction-resistance,By adding filler such as glass fiber,carbon fiber,copper powder,graphite,asbestos,MOS2,AL2O3,carbon powder,ceramic fiber, metal powder,polyamide,PS,the hardness,compression strength and abrasion resistance of the products is improved ,in addition,it will have good heat conductivity and low heat expansion coefficient.

-

3000mm Length PTFE Rod / Teflon Rods For Electrical Insulation , High Temperature Resistance

Extruded PTFE Teflon rod is manufactured by technics of paste extruding and ram extruding method in the diameter from 5 to 300mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of extruded teflon PTFE rod has similar friction levels to ice. Extruded teflon PTFE rod can work at -180°C ~+260°C and is the best electrical insulator of all known plastics. Extruded PTFE Rod is available in both virgin grades and reprocessed (mechanical) for less demanding applications.