Product Categories

Natural Transparant PFA Tube For Chemical Process / Heat Exchangers

Product number:KXT-PFA03

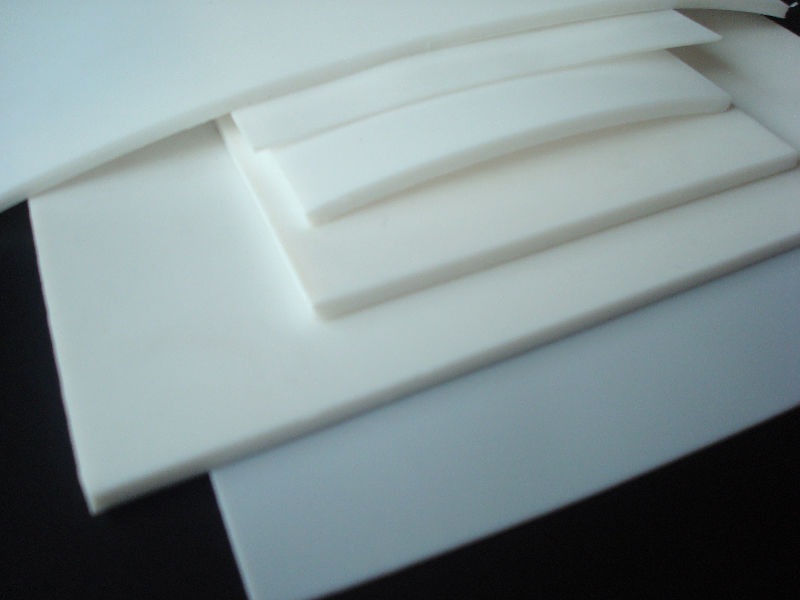

Quick Overview: PFA (PerFluoroAlkoxy) is similar to FEP (Polyfluoroethylenepropylene) in that PFA is a type of fluoropolymer that is similar to PTFE. PFA tubing is made from PFA resin and prepared by the technology of thermoplastic extrusion. It has good heat-resistance of -80+260,high purity and long flexible life ( 100 times of FEP tube).PFA tube is an ideal material in the applications of semi-conductor and long flexible life. Besides, PFA tube has good chemical-resistance, used as corrosive liquid and gas transportation and steel pipe liner etc. and electric insulation property. It is applied in the fields of petrochemical, semi-conductor, E/E, IT industry etc. PFA tubing is available in many standard sizes.

Send Inquiry

PDF DownLoad

Product Description

Quick Detail:

1.100% virgin grade high performance resins used to resist stress cracking

2.Chemically inert to nearly all industrial chemicals and solvents

3.Higher thermal stability than with FEP

4.Lower permeability than with FEP

5.Translucent

6.Moisture absorption nearly zero

7.FDA compliant for food contact

8.Non-flammable

9.Tubing is suitable for use with flare or conventional fittings

10.Tubing is available in coiled hose and convoluted constructions

11.Low permeation PFA tubing and pipe are also available

Applications:

Specifications:

Code

O.D.

O.D. Tolerance

W.T. Tolerance

PFA-G-1

1

±0.10

0.20±0.05

0.3±0.05

0.40±0.08

0.50±0.10

1.00±0.13

PFA-G-2

2

±0.10

PFA-G-3

3

±0.13

PFA-G-4

4

±0.13

PFA-G-5

5

±0.15

PFA-G-6

6

±0.15

PFA-G-8

8

±0.18

PFA-G-10

10

±0.18

PFA-G-12

12

±0.18

PFA-G-14

14

±0.18

PFA-G-16

16

±0.18

PFA-G-18

18

±0.18

PFA-G-20

20

±0.25

PFA-G-25

25

±0.25

PFA-G-32

32

±0.38

PFA-G-40

40

±0.38

PFA-G-50

50

±0.38

Note: Customers request negotiable

Main Properties

Item

Value

Relative Density

2.14~2.17

Tensile Strength MPa

Φ≤3mm

≥14.0

Φ3mm

≥18.0

Elongation @ Break %

Φ≤3mm

≥100

Φ3mm

≥200

Dielectric Strength KV/mm

wall thickness≤0.2mm

≥10

0.2mmwall thickness0.5mm

≥12

wall thickness≥0.5mm

≥15