Product Categories

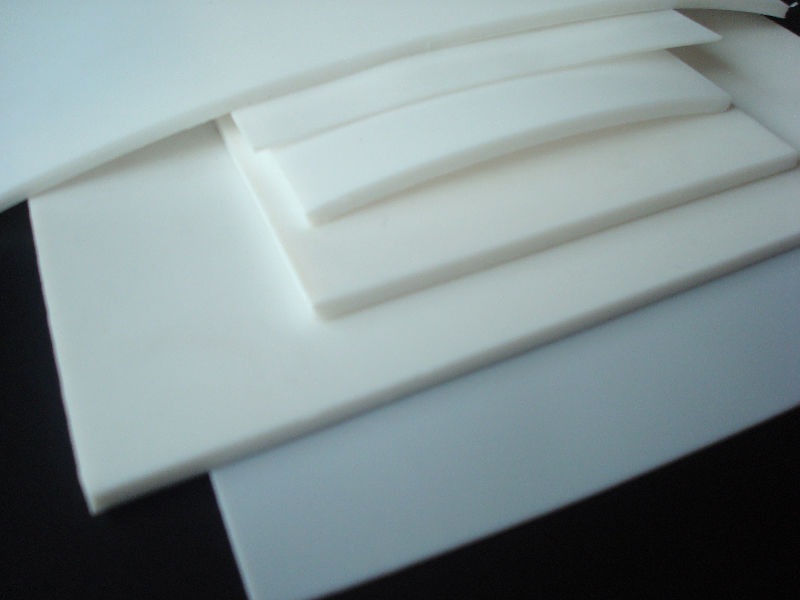

High Temperature Resistance Fep Resin / Fluoropolymer Resin Flame Retardant

Product number:kaxite-f13

Quick Overview: FEP resin is the copolymer of TFE and HFP, with good thermal stability, outstanding chemical inertness, good electrical insulation, and low coefficient of friction, enabling thermoplastic processing methods.

Send Inquiry

PDF DownLoad

Product Description

Detailed Product Description

Related Products

4000mm High Purity PVDF Sheet

Low Water Absorption PVDF Sheet

Acid-Resistant Light Weight PVDF Tube

Alkali-Resistant PVDF Tube

Electrical Insulation PFA Plastic Sheet

PVDF Material Heat Exchangers

Non-Stick PFA Plastic Sheet Food Processing

Translucent PFA Tubing Recyclable with FEP

FEP Rod For Petrochemical

White FEP Rod

Window FEP Tube FEP Sheet High Insulation

Industrial Fluorinated Ethylene Propylene Tube FEP Heat Shrink Tubing

PCTFE Tube For Instrumentation

Acid-Resistant PCTFE Rod

Brown PEEK Rods

Recycled PEEK Tube

High Elastic PEEK Rods

Bearing Grade PEEK Tube Chemical Resistance

Industrial Engineering Plastic Products

High Stiffness Industrial Engineering Plastics

Carbon Gland packing Solvent Resistance High Strength Self lubrication

Braided Packing For Pumps , Industrial Gland packing High Temperature Resistance Ceramic

Fiberglass Braided Gland Packing For Pumps Industrial Gland packing Good Sealing Properties

Industrial PTFE Gland Packing / Higher Strength And Better Corrosion Ramie Packing

Perfect Mechanical Strength And Long Elongations PU Sheets PU Squeegee

Radioresistance Fluoropolymer Resin / 30Mpa ETFE Resin For Cookware

Semitransparent Pellet Fluoropolymer Resin / FEP Resin Molding Grade For Chemical Industry

Milk White Fluoropolymer Resin / FEP Water Dispersion For Coating

High Tensile Strength PTFE Powder Resin For Extruded Tube , White Loose Powder

Anti-Corrosion Fluoropolymer Resin / 29Mpa PFA Resin For Heat Exchanger

PTFE Teflon Dispersion With High Molecular Weight For Impregnation Of Glass Fiber

White Liquid Fluoropolymer Resin , PTFE Teflon Dispersion For Nonstick Coating

White Liquid Fluoropolymer Resin , PTFE Teflon Dispersion For Nonstick Coating

Yellowish Liquid PTFE Teflon Dispersion With High Viscosity , Stick Metal Available

OEM ODM Fluoropolymer Resin / 28Mpa Foaming FEP Resin , Electronic Properties

Color Powder PTFE Teflon Powder Resin , Fluoropolymer Resin For Extruded Rod

Oil Resistance / Anti-Corrosion Fluoropolymer Resin PFA Resin For Steam Pipe

High Tensile Strength Fluoropolymer Resin PTFE Resin For Make Extruded Tube

High Temperature Resistance Fep Resin / Fluoropolymer Resin Flame Retardant

High Temperature Resistance Fep Resin / Fluoropolymer Resin Flame Retardant

37.5Mpa Fluoropolymer Resin / White Loose Powder For Extruded Plate

500 - 800g/l Fluoropolymer Resin / PTFE Teflon Resin For Making Extruded Rod

High Purity Fluoropolymer Resin / PTFE Teflon Resin For Making Tube

High Purity White Powder PTFE Teflon Resin For Making Rod , No Impurities

PTFE Teflon fine powder resin is suitable for plaster extrusion making small-diameter, thin wall pipe, lead

24Mpa Fluoropolymer Resin , PTFE Teflon Powder Resin / White Loose Powder For Seal Tape

Expanded PTFE Coated Fiberglass Cloth For Wires , 0.2g/cm3 - 1.2g/cm³

Brown PTFE Coated Fiberglass Cloth Oven Liner Sheets Heat-resistance

Black Polytetrafluoroethylene PTFE Etched Teflon Sheet Heat-resistant

Graphite Filled PTFE Coated Fiberglass Cloth Microwave Liner

Black PTFE Coated Fiberglass Fabric Poly Tetra Fluoro Ethylene

Bronze Filled PTFE Coated Fiberglass Cloth Chemical Resistance

Non-Stick PTFE Teflon Tape Graphite Filled Teflon High Temperature

Sealing PTFE Coated Fiberglass Cloth High Temp Fiberglass Tape

PTFE Teflon Tape Coated Fiberglass / PTFE Micro-Porous Membrane

Food Industry PTFE Coated Fiberglass Cloth / PTFE Teflon Film

White PTFE Coated Fiberglass Fabric Expanded Polytetrafluoroethylene Tape

High Temperature PTFE Coated Fiberglass Cloth / Fabric Chemical Processing

Insulation High Temp Fiberglass Tape / Heat Resistant PTFE Glass Cloth Tape

0.2g/cm³ White PTFE Coated Fiberglass Cloth Non-Stick Teflon Sheet

High Temperature Teflon PTFE Tape Non-stick Food Grade For Cooking

PTFE Coated Fiberglass Cloth / High Temperature Fiberglass Tape Cooking Liner