Product classification

Fluoropolymer Resin

-

Radioresistance Fluoropolymer Resin / 30Mpa ETFE Resin For Cookware

ETFE resin has the advantage of both PTFE&TFE. It has perfect insulativity,thermo chemical,thermo to aging,radioresistance and easily to process.Also with well toughness,hardness,cold flow and creep deformation etc.ETFE has been widely used in aviation,spaceflight,semiconductor,petrochemical heavy-duty,seal material and solar industy.

-

Semitransparent Pellet Fluoropolymer Resin / FEP Resin Molding Grade For Chemical Industry

FEP Molding (Lining) Grade resin is the copolymer of tetrafluoroethylene (TFE) and hexafluoropropylene (HFP) with excellent thermo-stability and chemical inertness, outstanding electrical insulation and very low friction coefficient. The thermoplastic process techniques can be used to fabricate useful products from FEP.

-

Milk White Fluoropolymer Resin / FEP Water Dispersion For Coating

FEP water dispersion is formed through copolymerization of tetrafluoroethylene and hexafluoropropylene. FEP water dispersion is truly thermoplastic resin with excellent typical features: continuous use temperature of 200 ℃, the maximum temperature to 240 ℃, for almost all industrial chemicals and solvents show chemical inertness. FEP water dispersion has excellent heat resistance, corrosion resistance, excellent chemical inertness, good electrical insulating properties and low coefficient of friction.

-

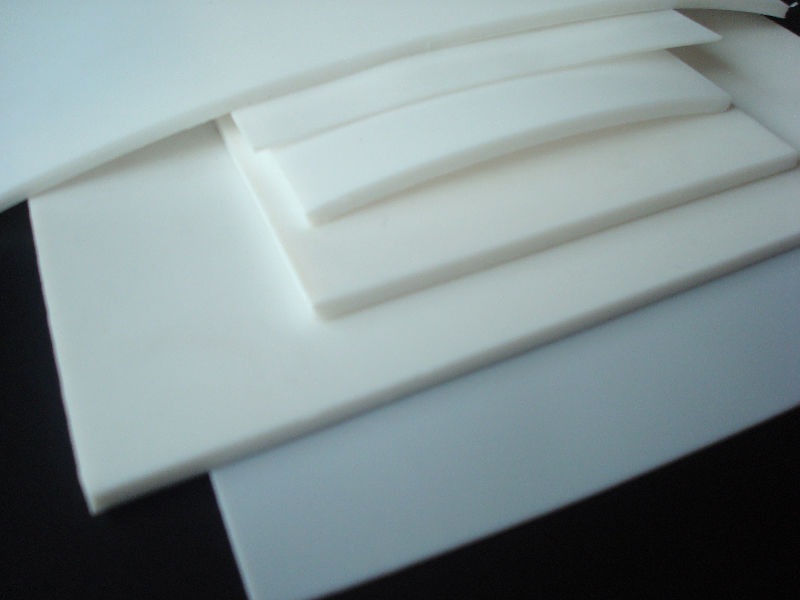

High Tensile Strength PTFE Powder Resin For Extruded Tube , White Loose Powder

PTFE Teflon fine powder is suitable for plaster extrusion making small-diameter, thin wall pipe, lead and cable raw material tape, porous sealing material etc.

-

Anti-Corrosion Fluoropolymer Resin / 29Mpa PFA Resin For Heat Exchanger

PFA resin its chemical stability properties, physical and mechanical performance, electrical insulating properties, lubricity, not sticky, aging and incombustible are very fine, all and assembled tetrachloroethylene similar. Also has the same tetrachloroethylene and assembled the thermal stability, PFA resin is suitable for electrical and electronic industry insulating layer, high frequency and uhf wire insulation, electronic devices, insulation parts cable insulation and sheath, connector plug,bearing insulation, printed circuit boards, electrostatic megaphone to use membrane, etc. Especially the small size thin-wall insulation line, its processing speed is more then general PTFE twined materials many times

-

PTFE Teflon Dispersion With High Molecular Weight For Impregnation Of Glass Fiber

1.Has good stability, suitable for any mixing process. 2.The madest content of Surfactant help to increase wetting and sticking performance. 3.Has high molecular weight and suitable for high temperature cooling process,to improve the polish of the appearance.

-

White Liquid Fluoropolymer Resin , PTFE Teflon Dispersion For Nonstick Coating

1.Has good stability, suitable for any mixing process. 2.The content of Surfactant help to increase wetting and sticking performance. 3.Has high molecular weight and suitable for high temperature cooling process,to improve the polish of the appearance.

-

White Liquid Fluoropolymer Resin , PTFE Teflon Dispersion For Nonstick Coating

1.Has good stability, suitable for any mixing process. 2.The content of Surfactant help to increase wetting and sticking performance. 3.Has high molecular weight and suitable for high temperature cooling process,to improve the polish of the appearance.

-

Yellowish Liquid PTFE Teflon Dispersion With High Viscosity , Stick Metal Available

High viscosity Can impregnate glass fiber several times to get sicker coating It can stick with metal perfectly

-

OEM ODM Fluoropolymer Resin / 28Mpa Foaming FEP Resin , Electronic Properties

Foaming FEP resin enhances its electronic properties, providing opportunities for miniaturization and weight savings. Foaming FEP are known for high-frequency signal transmission with minimal distortion. It's ideal for producing coaxial cable cores in a broad rang of sizes.